|

Advantages of the P-SystemThe advantages of the P-System and its Clamex P-14, Tenso P-14 and Divario P-18 connectors are also being integrated into CNC production. Several thousand companies worldwide use the inserting system on their CNC routers. This process is expedited by the integration of macros in many new machines and by adapting existing products to the P-System, for example the Weeke BHX 200 or the Benz Flex 5+C aggregate.

Thanks to the efficient cutting of the P-system groove, using P-system connectors is even more efficient and reliable. |

|

|

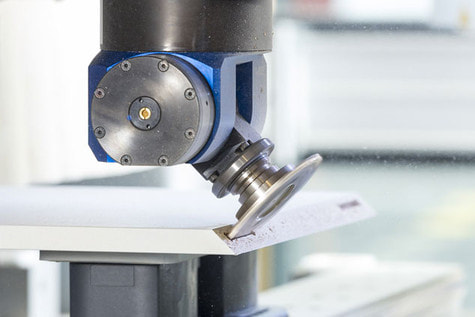

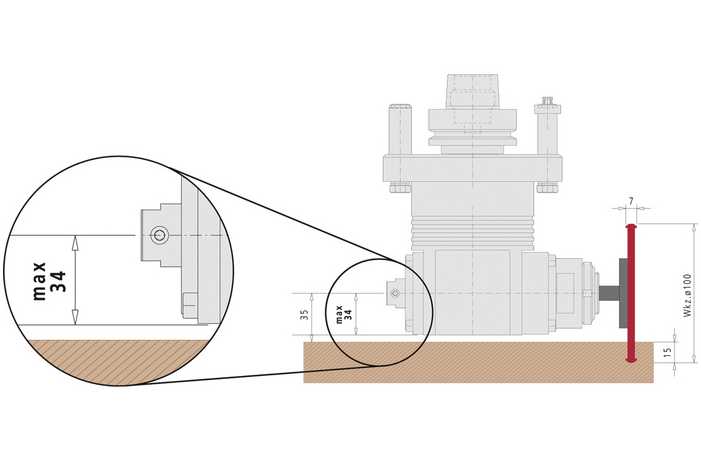

Swivelling aggregate heads, such as the Flex 5+C from Benz, enable P-System grooves to be cut at any angle. It is thus possible to utilize this connecting system and to join and clamp pieces together at all sorts of different angles.

|

Efficiently clamp or glue miters or butt joints together using Tenso or Clamex or create detachable joints.

|

Ideal for machining on CNC machining centers with pod and rail or nesting technology – whatever your production philosophy. Hybrid CNC and Zeta-P2 solutions are readily available as well, when using aggregate heads is not an option.

|

Integration of the P-System with vertical machining centers from Homag, Holz-Her and Biesse is one of the fastest ways of creating P-System grooves

|

Cabineo is the newest connector from Lamello, and is an outstanding solution for cabinet shops and manufacturers using nested-based CNC routers. The toolpath may be quickly machined with a standard, straight-shank router bit without a tool change. The Cabineo connectors are simply tapped into the routed pocket and join cabinet components together by screwing into a mating 5mm shelf pin hole with nearly 200 pounds of clamping force. Cabineo may be covered with aesthetic cover caps, or parts may be inverted to allow for a completely invisible application. Because there is no pin or stud required with Cabineo, all components may be shipped to the jobsite as a true flat-pack, RTA solution. The M6 version of the Cabineo connector uses a metal helical insert or may be fastened directly into a tapped hole in metal furniture or fixture components.

More Advantages

More Advantages

- Installation of fixed shelves or vertical dividers in an already assembled unit

- Detachable for transport or if the fixed shelves need adjusting

- Shallow element of 10 mm allows for panels from 12 mm thickness

- Corner joints with Cabineo 12 (drill hole Ø 5 × 12 mm)

- Dividing panel joints with Cabineo 8 (drill hole Ø 5 × 8 mm) from material thickness 16mm

- Use with or without cover caps. Cover caps are available in various colors

- Metal insert threaded version available for exceptionally strong connections or for wood-to-metal component connections

Benefits

Time-savings for the whole production process! Simple, Fast & Strong!

1. Time-saving in production

1. Time-saving in production

- Optimized process due to surface machining; no edge drilling necessary

- Only one tool change from 5 mm to 15 mm drill; or rout the profiled shape with no tool change - use a standard CNC spiral bit

- No dowel holes means less drill holes

- Efficient pre-installation of the one-piece connector in the factory

- Flat-Pack delivery with pre-installed connectors

- Connectors delivered installed in the workpiece; thus no hardware needs to be shipped separately

- One-piece connector without dowels; no pre-assembly of screws or dowels in the side panels necessary

- Easy positioning in the drill hole due to the protruding screw

- Fast assembly with a cordless drill