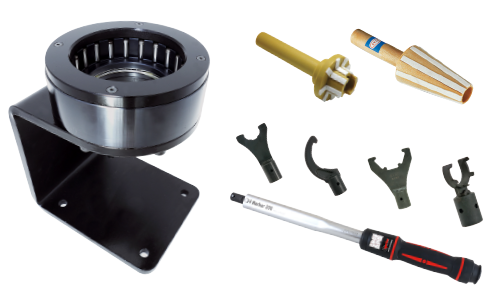

We recommend using a tightening fixture and torque wrench to make sure cutting tools and retention knobs are properly tightened. Over-tightening can distort or even crack collets, causing run-out problems and premature failure of the collet, nut, tool holder and cutting tool. Under-tightening can also cause poor cutting performance, or allow cutting tools to fly out of the spindle – a very serious safety hazard.

Collet and Tool Holder Clamp Setup Procedure

- Snap collet into nut

- Insert cutter into collet

- Collets without counter bore require shank to extend to the bottom of the collet

- Hand tighten collet nut assembly into tool holder

- Insert tool holder assembly into tightening fixture and secure it

- Tighten collet nut to recommended torque using a torque wrench and adapter

Torque Setting Chart for CNC Collets

Keeping your CNC tool holders clean is just as important as keeping your cutting tools sharp. Proper maintenance not only helps your CNC machine run in the most efficient way, it can prevent tool breakage, premature wear of the holder, seizing of locking nut and rust.

Inspection and cleaning of CNC Tool Holders and Spindles should be done frequently. A proper inspection includes taking the tool holder apart and cleaning it. Residue can be left behind by which affects the efficiency of the cutting process.

When cleaning your machine parts, only use lint free dry cloths. Wipe the entire holder carefully. Then apply a light coat of penetrating rust inhibiting lubricant; this helps to prevent rust and keeps corrosion to a minimum. Use only wiping tools made specifically for cleaning your machine. In summary:

1. Use the air nozzle to loosen and remove any build up or debris.

2. Wipe holder/tool with lint free cloth or cleaning kit made for your style holder.

3. If first two steps are not satisfactory, use pitch/lubricant degreaser spray for your industry. Wipe clean.

4. Clean threads of holder and nut with nylon or bronze bristle brush.

5. Wipe clean entire holder and nut with denatured alcohol removing residue.

6. Spray Lusin G31 anti corrosion protect spray to prevent any rust on your tools.

Inspection and cleaning of CNC Tool Holders and Spindles should be done frequently. A proper inspection includes taking the tool holder apart and cleaning it. Residue can be left behind by which affects the efficiency of the cutting process.

When cleaning your machine parts, only use lint free dry cloths. Wipe the entire holder carefully. Then apply a light coat of penetrating rust inhibiting lubricant; this helps to prevent rust and keeps corrosion to a minimum. Use only wiping tools made specifically for cleaning your machine. In summary:

1. Use the air nozzle to loosen and remove any build up or debris.

2. Wipe holder/tool with lint free cloth or cleaning kit made for your style holder.

3. If first two steps are not satisfactory, use pitch/lubricant degreaser spray for your industry. Wipe clean.

4. Clean threads of holder and nut with nylon or bronze bristle brush.

5. Wipe clean entire holder and nut with denatured alcohol removing residue.

6. Spray Lusin G31 anti corrosion protect spray to prevent any rust on your tools.